OUR HISTORY

ALWAYS SEEKING

NEW CHALLENGES

Since 1976

The entrepreneurial idea and spirit of five friends and colleagues gave birth to C.S.C. on 22 May 1976.

The experience of Antonio Dalle Carbonare, the meticulousness of Alessandro Pamato, the versatility of Leonida Dal Santo, the perseverance of Mariano Scortegagna, the business acumen of Gino Dal Santo, together with the capacity of the newly arrived Maria Conzato to coordinate everything, were the winning ingredients that made it possible for the company to make headway through competitors, gaining more ground day by day.

1976

C.S.C. WAS BORN

The 1980s

AEROSPACE INDUSTRY, PHYSICS INSTITUTES, AND NAVAL SECTOR

During the 1980s collaboration began with the most important research centres, physics centres, and aerospace industry.

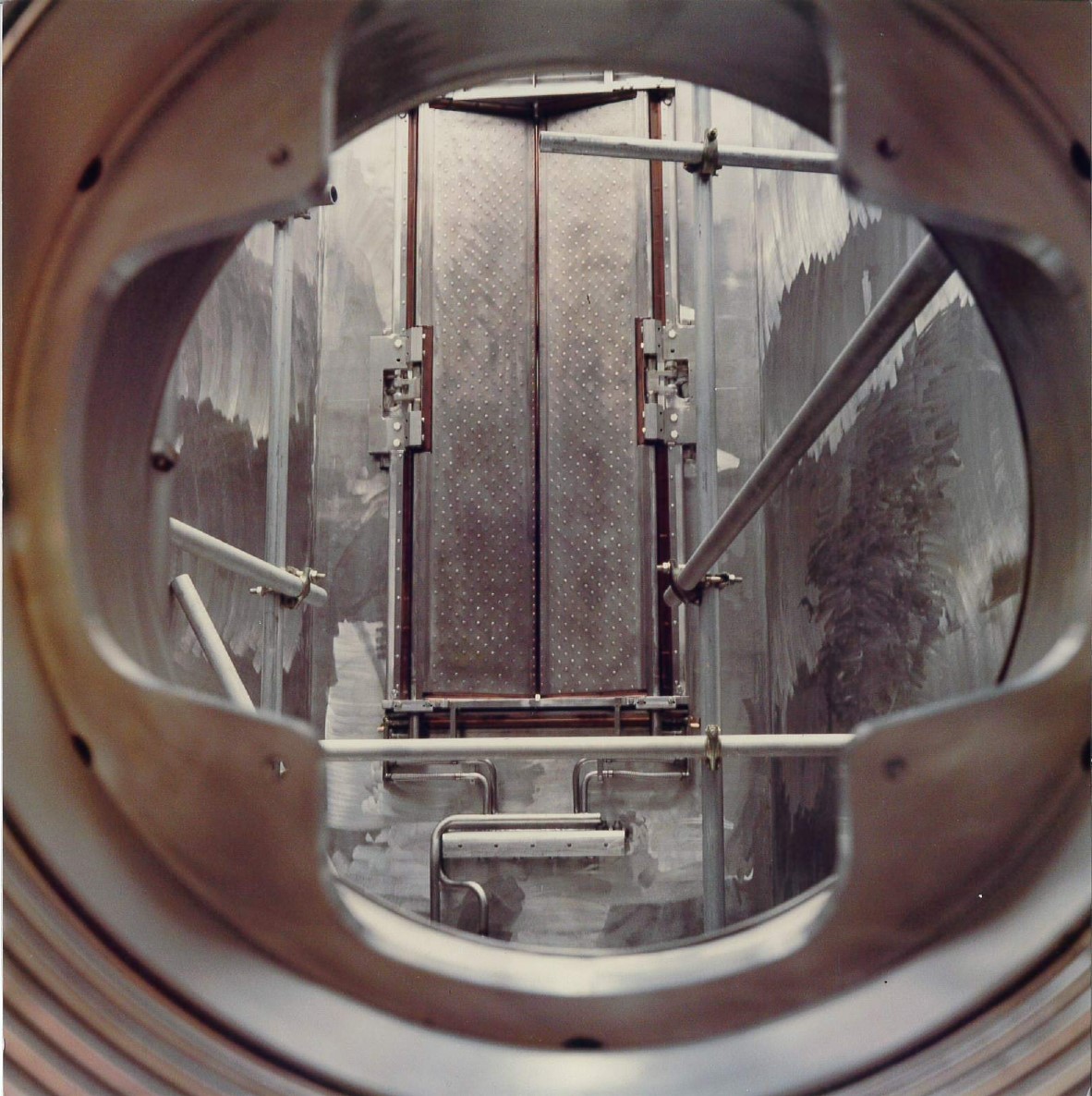

C.S.C. designed and built the “Fast Shutter” in aeronautic titanium for experimental nuclear fusion reactors known as JET (Joint European Torus). For the same project, the company built thermal shields for the support structure of the toroidal vacuum chamber.

With the availability of the new “clean room” and the know-how acquired in the aerospace sector, C.S.C. then constructed for Nasa, thanks to a contract with SNIA, two control units for the loading of fuel onto geostationary satellites and some components for the Space Tethered.

During these years the company also entered into collaboration with Riva Calzoni in Milan for the construction of hydraulic components for vertical pump bodies and water jets for propelling boats and ships.

In 1990 the company entered the racing industry, creating a variety of components in Titanium Grade 5 for one of the most famous racing sailboats: the Moro di Venezia.

1993 was the year C.S.C. achieved ISO 9001 quality certification, becoming one of the first SMBs to certify its own quality system.

Moreover, with the collaboration of NFN in Genoa, the company began planning and building two electromagnetic calorimeter modules to detect photons and neutrons of the CLAS detector installed in the Jefferson Laboratories in the USA.

A few years later, C.S.C. was to be one of the first Italian companies to create a heat exchanger with a tantalum tube bundle with the project approved and the device tested by ISPESL under VSR ’95.

1990s

ENTERING THE RACING INDUSTRY AND ISO 9001 CERTIFICATION

The 2000s

THE SECOND GENERATION TAKES THE HELM AT C.S.C.

C.S.C. created motorcycle frames for the RS Cube di Aprilia project by Aprilia for their debut in the World Class 500cc Championship.

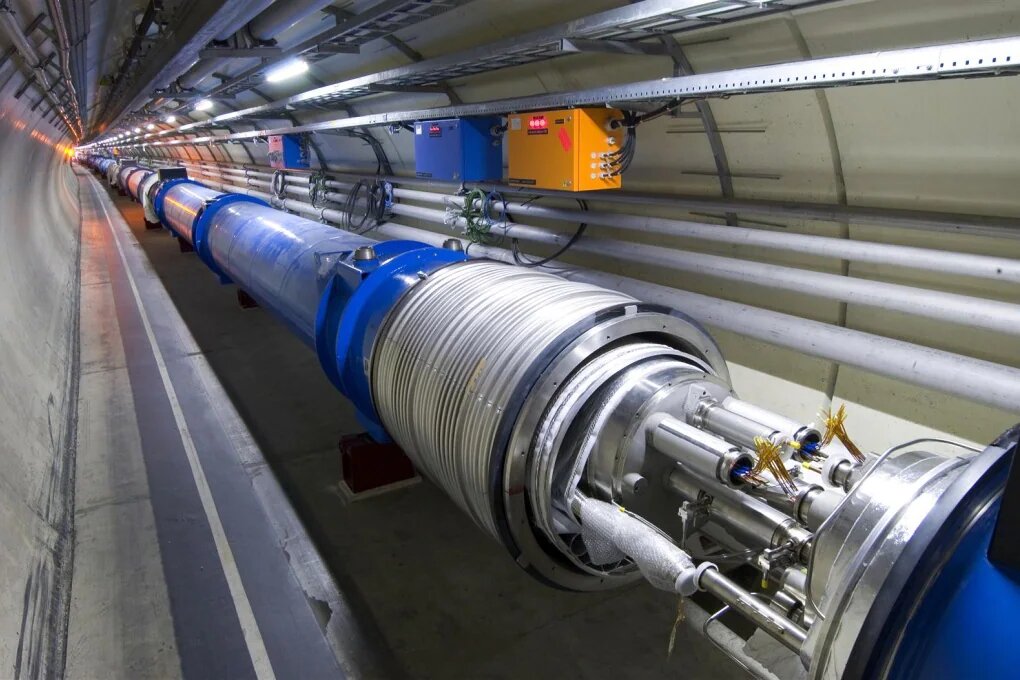

For the Large Hadron Collider (LHC) project of CERN, the company created a series of components that constituted the heart of the largest and most powerful particle accelerator in the world.

In 2003 the company was passed down to the second generation. Franco Dalle Carbonare, Adelucio dal Santo, Marco Scortegagna, and Riccardo Pamato – who had been working in the company for some time and were proud of their inheritance – accepted the challenge to continue what had been started by their parents in the best possible way. The same year saw the addition of the C.S.C. Trading Division, a branch dedicated to the marketing of special alloys like Duplex and Super Duplex. .

Over these years, thanks to the collaboration with ASG Superconductors, the CPS and DPS Cryostats were created for the Katrin Project of the German Karlsruhe Institute of Technology (KIT).

For the XFEL project of the DESY Institute in Hamburg, Germany, 272 Helium Tanks in Grade 2 Titanium were constructed, marking the beginning of the manufacturing of such LINAC components for several research institutes.

There is a little piece of C.S.C. also in Azzam, the largest private yacht in the world, for which the company manufactured the water jets.

Over the same years, water jets were also created for the first LNG gas-propelled ferryboat christened with the name “Papa Francesco”.

After 10 years of activity, successes and commercial agreements stipulated with some of the most important steel manufacturers, the Trading Division of C.S.C. was rebranded into SpecialSteelStock.

The 2010s

MAJOR PROJECTS AND THE BIRTH OF SPECIAL STEEL STOCK

2020s

NEW MANUFACTURING PLANT AND OFFICES

The new plant and offices located on via Luigi Cazzola in Schio become operative in April 2021, allowing for a larger workshop area (+2600 sqm) and increased manufacturing capacities (+2mt height capacity and +20t lifting capacity).

SpecialSteelStock also sees an increase in its stock surface as it is now housed in the entire former plant.

Continuous evolution in technology innovation means also new measurement and dimensional control systems such as a 3D Laser Scanner for a more reliable manufacturing and control tool for highly complex surfaces.